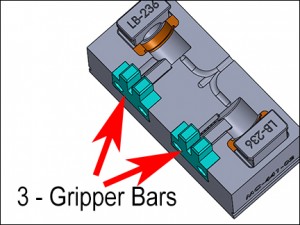

The heart of a properly designed and manufactured molded cable assembly is a fully encapsulated contact and wire termination point for strain relief and mechanical advantage. Before embarking on any overmolding design project several design considerations should be explored first.

Overmolding Ultimate Guide Best Molding Companies In The Usa

Download our product selector guide.

. The two shot molding process includes the following steps. After the substrate has cooled the mold opens and the B-Plate movable side of the mold rotates 180 without ejection of the substrate. Overmolding a cable connector typically employs a two-step process.

Overmolding is 90 percent mechanical and 10 percent cosmetic. Once the required temperature has been achieved the mould opens and an array of pins sleeves strippers etc. If the overmold is only on one side of the part the two B-side cavities are identical.

CNC Surface Finish Guide. Part Design and Tooling. This guide is a compilation of over thirteen years of experience in the developmentdesign and processing of overmolding TPEsbased on contributions from a variety of GLS and industry sources.

Use mechanical interlocks to reinforce the overmolding. Ensure the thickness of the TPE overmolding is sufficient enough not to cause delamination. Table of Contents Introduction 1.

One of the most common applications is to add a soft functional hand-friendly layer of rubber-like material. In addition the wires are encapsulated inside the molding which creates a barrier preventing liq uidmoisture from entering the equipment through the connector or cable jacket if breached. GLS Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded products.

Typically molded circular connectors have an internal premold which is the part of a molded connector. Overmolding is an injection molding process that allows an additional layer of resin to be added to an existing molded part to provide a combination of characteristics that no single material can provide. Table of Contents Introduction 1.

It provides insights between cost and performance trade-offs for the most common design decisions faced by cable assembly designers in the Consumer and commercial markets. This includes grommets as part of the assembly for any points where an assembly needs to be. Santoprene TPV a tough but flexible vulcanizate widely used in weatherseal food service and wire and cable applications is more restrictive readily bonding to polypropylene but little else.

This includes grommets as part of the assembly for any points where an assembly needs to be installed through a housingopening and as a covering for the connector backshells to protect the. Consider these helpful tips. Silicone overmolding is also known as rubber overmolding liquid silicone overmolding lsr overmolding insert overmolding multi-shot injection molding as a process that apply silicone rubber part - overmold onto the second part - substrate by compression molding transfer molding plastic.

Overmolding Design Considerations When designing cable assemblies engineers are using the overmolding process to provide strain or bend relief. Are you looking for some basic tips to get started or ways to improve your design. Elimination of Fasteners and Adhesive.

This guide is a compilation of more than 25 years of experience in the de velopment design and processing of over molding TPEs based on contributions from a variety of Avient and industry sources. The process of overmolding helps to create a material bond around wirecables PCBs and connectors that provide watertight seals. Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded pr oducts.

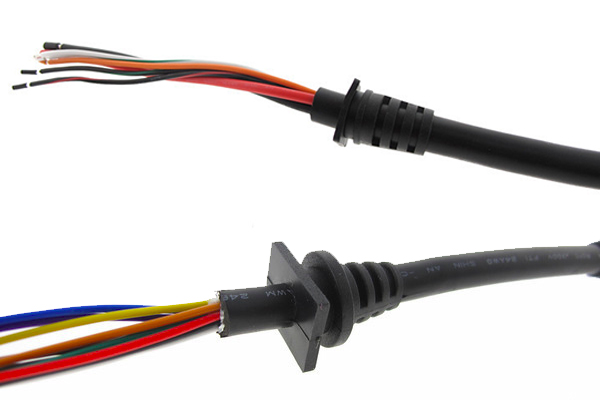

Barrel A fills the substrate set of cavities. Overmolding Design Considerations When designing cable assemblies engineers are using the overmolding process to provide strain or bend relief. Various overmolded cable assemblies custom manufactured for each application.

NUMBERWe reserve the right to. As a result the overmolded electrical assembly can achieve IP67 IP68 and IP69K standards. Various colors textures and graphics available.

Size Maximum Dimensions IN MM Height may be limited if using a silicone as the overmold material and deeper parts are limited to a smaller outline. This cable overmolding design guide will result in. This includes grommets as part of the assembly for any points where an assembly needs to be installed through a housingopening and as a covering for the connector backshells to protect the termination points and contacts.

Our basic guidelines for overmolding and insert molding include important design considerations to help improve part manufacturability enhance cosmetic appearance and reduce overall production time. Apply the Inner Mold The first step is to apply an inner mold which is used to encapsulate the terminations and the cable wires as well as provide a support structure for the exterior or cosmetic outer mold. Silicone Overmolding Design Guide.

Ad Tight-tolerance custom molded plastic parts from prototype to large-scale production runs. Overmolding is an injection molding process that allows an additional layer of resin to be added to an existing molded part to provide a combination of characteristics that no single material can provide. This helps to protect electrical components from dust dirt and debris.

Overmoulding is a process that further enhances the sealing properties and helps to minimize stress on the cable termination to the connector. The guide will make cable overmolding design guide. Overview The intent of this guide is to assist cable assembly designers in selecting readily available components when possible to minimize sample preproduction and production lead times.

Overmolding Design Considerations When designing cable assemblies engineers are using the overmolding process to provide strain or bend relief.

Incorporating Pcbs And Leds Into An Outdoor Overmolded Cable Design

Cable Overmolding Materials And Colors

Everything To Know About Custom Overmolded Cable Assemblies

Guide To Designing A Custom Cable P Ii Blogs Teletec Electronics

Molded Strain Reliefs Custom Overmolded Strain Reliefs

Cable Assembly Manufacturing Outsource Overmolding Technology And Know How Consulting Tool Design And Development Application Engineering And Technical Marketing Support To Oem And Cable Assemblies Companies Requiring The Development Or Expansion

0 comments

Post a Comment